Phone: +55 (19) 3535-6550

E-mail: sulplast@sulplast.com.br

Av. Sulplast, 1969 - Distrito Industrial - Rio Claro/SP - Brazil - 13505-680 - Webmail

Technologies and processes

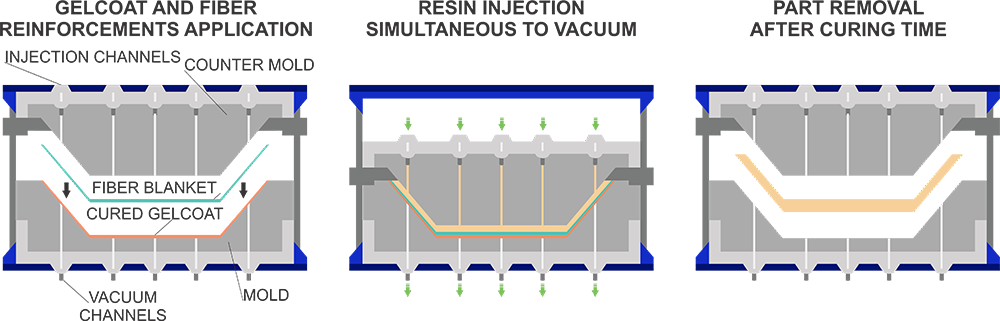

Resin Transfer Molding Light (RTM Light)

Most suitable for medium and high volume production, the RTM Light process is widely used in the construction of structural parts for the automotive, agro vehicles, civil construction and mining segments.

Technology derived from the RTM Conventional, but with faster production cycles and lower tooling costs, the RTM Light is a thermoset manufacturing process that allows the development of geometrically complex parts, with high mechanical resistance and smooth finish on both sides.

Closed mold process, the first stage of RTM Light, consists of applying the gel coat to the molding surface, positioning the fiberglass blankets and possible reinforcements, and then closing it with the counter mold. At the end of this step, the resin starts to be injected with low pressure simultaneously with the vacuum action, until the material fills the entire space of the mold cavity. After waiting on the complete curing time of the polymer, the part is then removed from the mold.

As a supplier of technical parts in RTM Light, Sulplast is extremely renowned in the market, delivering complete systems/solutions in RTM Light, with a very high quality standard for different economic sectors from all over Brazil, proudly receiving several awards throughout its history, for its efficiency as a supplier of parts in RTM Light and many other plastic transformation processes.