Phone: +55 (19) 3535-6550

E-mail: sulplast@sulplast.com.br

Av. Sulplast, 1969 - Distrito Industrial - Rio Claro/SP - Brazil - 13505-680 - Webmail

Technologies and processes

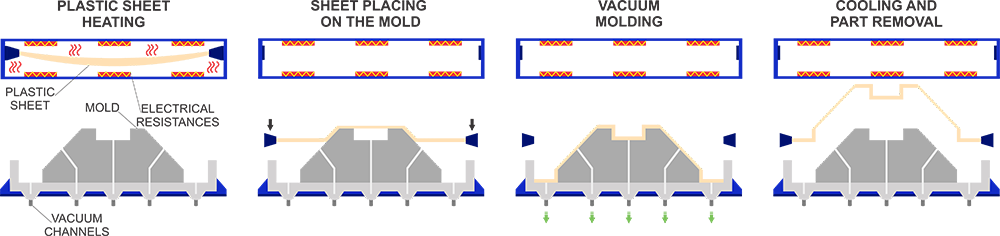

Vacuum Forming

Vacuum Forming, is a thermoforming process able to transform sheets of different colors and plastic materials (ABS, PP, HDPE, PS, Noryl, ABS + PMMA etc.), into highly complex technical parts, by means of vacuum suction systems.

Capable of serving various industrial segments such as trucks, buses, cars, agro vehicles, refrigeration, construction and mining machinery, the Vacuum Forming process produces bumpers, fairings, covers, panels, protections and many other parts, which efficiently fulfill stricter product performance requirements, in terms of dimensional, design, weather resistance (UV radiation), durability and many other requirements.

In the Vacuum Forming process, the plastic sheet is positioned in the frame of the thermoforming machine, where it will be heated uniformly by electrical resistances. Then, by means of vacuum suction, the material adheres to the molding surface and takes on its shape. After cooling, the plastic part is removed from the forming structure and finalized with finishing procedures such as cutting and painting, according to the specifications of each project.

With a strong presence in the market for more than 40 years, throughout its history as a supplier of technical parts, Sulplast has developed differentiated structure and know-how, which make the company internationally competitive in the Vacuum Forming segment.

Capable of extruding the plates themselves and counting on an extremely modern robotic finishing process, Sulplast is currently recognized as a reference supplier of parts in Vacuum Forming, which continuously invests in new technologies and high performance materials, to deliver to its customers solutions in Vacuum Forming; always with quality and cost-benefit.